스포트라이트

Equipment Technician, Equipment Assembler, Equipment Maintenance Technician, Equipment Operator, Equipment Engineer, Manufacturing Technician, Fabrication Specialist, Mechanical Assembler, Machine Builder, Production Technician

The term “equipment” covers thousands of different items used in countless industries. Bulldozers, blenders, blood pressure monitors. Computers, car jacks, dumbbells. Voltage testers, Bunsen burners, fire extinguishers…the list goes on and on.

Equipment is used to perform or assist with all sorts of tasks and functions. It’s usually purchased commercially and “off-the-shelf,” meaning it already exists and is easy to buy. But sometimes there are tasks that need doing—and no existing equipment designed to do them! That’s where Equipment Fabricators come in to save the day.

As a process, fabrication is related to machining but involves more cutting, bending, welding, shearing, and forming pieces. Machining, on the other hand, relies more on milling, turning, drilling, grinding, and lathing.

Fabricated equipment refers to custom-made devices or tools specially created for unique purposes. Such equipment may include customized machines for industrial purposes, special rigs for filming, tailored medical devices, research and lab apparatus, vehicle modifications, sporting gear, etc. Whatever it is, Equipment Fabricators are always up for the challenge!

- Getting to design, manufacture, and assemble new equipment to help organizations meet their goals

- Potentially making something that will revolutionize an industry

- Unique opportunities for skills development

근무 일정

- Equipment Fabricators work full-time jobs, typically with nights, weekends, and holidays off, though overtime may be occasionally needed to stay on schedule.

일반적인 의무

- Meet with managers or clients to review their requirements for fabricated equipment

- Brainstorm ideas for what such equipment might look like, its features, and the estimated cost of productionIf multiple pieces of equipment are needed, review manufacturing procedures and costs

- Create or review written descriptions or sketches, blueprints, technical drawings, etc.

- Agree upon the terms of work, including timelines and budgets

- Collaborate with team members, including engineers or consultants, as needed

- Request the equipment, tools, and raw materials necessary to begin work

- Use hand tools and operate machines to fabricate workpieces. Assemble parts when ready

- Mark cutting lines on materials; check to ensure pieces are securely fitted and aligned

- Examine parts or final products for quality assurance

- Conduct stress tests and troubleshoot prototypes to ensure proper functioning before submitting them for review

- Garner feedback and make adjustments

추가 책임

- Attend equipment/product development meetings

- Adhere to safety standards and guidelines

- Create detailed reports of all work

- Write or help write operation manuals for new equipment

- Stay up-to-date on applicable software and technical manuals

- Train and mentor new fabricators, machinists, operators, technologists, and technicians, as needed

- 작업 공간을 청결하게 유지하고 기계에 대한 정기적인 유지보수 수행

소프트 스킬

- 경보

- 분석

- 주의

- 의사소통 기술

- 규정 준수 지향

- 비판적 사고

- 디테일 지향

- 징계

- 독립의

- 목표

- 조직

- 환자

- 계획 및 구성

- 문제 해결

- Safety-consciousness

- 건전한 판단

- 체력

- 팀워크

- 시간 관리

기술 능력

- 청사진 읽기

- Welding/metalwork

- Machining and machinist programs such as Armchair Machinist and Machinists’ Calculator

- Computer-aided design programs like Autodesk AutoCAD, CATIA, PTC Creo Parametric, and SolidCAM

- 오토데스크 퓨전 360 및 CNC 마스터캠과 같은 컴퓨터 지원 제조 소프트웨어

- 산업용 제어 소프트웨어(예: 편집CNC 또는 마작 마자트롤)

- 헥사곤 메트롤로지 PC-DMIS와 같은 절차 관리 프로그램

- Precision measurement tools (calipers, micrometers, and gauges)

- Knowledge of materials and their properties (including various types of metal and metal alloys such as steel, brass, aluminum, copper, zinc, lead, vanadium, and manganese)

- Familiarity with tools and equipment such as welding machines, shears, presses, grinders, CNC machines, lasers, plasma cutters, waterjets, measuring instruments, and safety gear

- 유압 시스템, 전기 배선, 윤활유 및 배터리에 대한 지식이 있어야 합니다.

- Safety procedures and first aid

- Aerospace industry

- Agribusiness

- 자동차 산업

- Computer and electronic product manufacturing

- 건설 회사

- Food processing industry

- 기계 제조

- Oil and gas companies

- Renewable energy sector

- 연구 및 개발

- Temporary help services

- 운송 장비 제조

Equipment fabricators must maintain high levels of precision and deliver quality prototypes and finished products that meet their employer’s or client’s expectations. Work must be done safely, within established timeframes and budgets, and in compliance with applicable industry standards.

These numerous demands put a lot of pressure on fabricators, whose work is heavily scrutinized. When things get behind schedule, they may have to put in extra hours to catch up. It’s a physically demanding job, involving lifting, prolonged standing, and exposure to various hazards—all of which can take a toll over time.

Trends in the field of equipment fabrication include the rise of Industry 4.0, which uses technologies like automation, artificial intelligence, Cyber-Physical Systems, cloud computing, 3D printing, and the Internet of Things to improve efficiency and productivity.

For equipment that will be mass-produced, the Industrial Internet of Things enables manufacturers to connect machines, devices, and sensors to the Internet. This allows real-time data collection, helping to optimize operations. Sustainable Manufacturing is another growing trend, as companies seek to reduce waste, improve energy efficiency, and utilize renewable resources. However, this may be less important for customized equipment that will only be made once or a few times.

Equipment Fabricators enjoy visualizing ideas and using their hands to bring them to life. They are comfortable using tools and stationary heavy equipment. They might have enjoyed math and shop classes in school, as well as design and computer programming.

For them, it’s easy to collaborate but they don’t mind working alone for long periods where they can focus on the task at hand. They might have been highly independent growing up, and thus feel right at home completing projects without a ton of interaction with others.

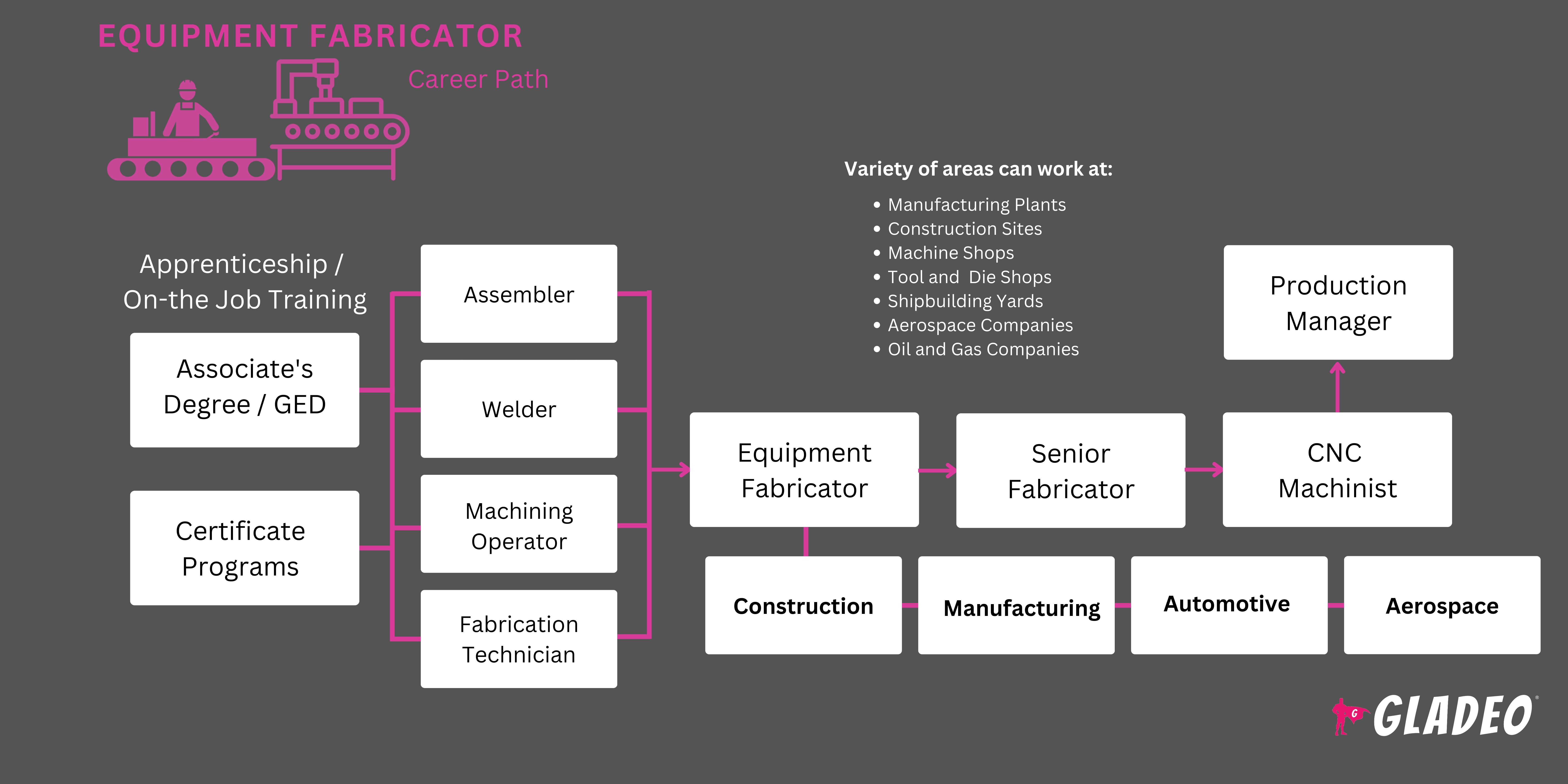

- Equipment Fabricators need at least a high school diploma or GED

- Many workers in this field pursue a certificate or associate’s degree at a community college or technical school to learn or brush up on:

- 수학

- 청사진 읽기

- Welding/metalwork

- Safe hand tool usage

- CAD/CAM programs

- How to operate CNC machines

- 기타 일반적인 과정은 다음과 같습니다:

- Aluminum Projects

- Bending

- Notching

- Part Forming & Construction

- Mill & Lathe Operations

- Sheet Metal Shaping

- Plasma Cutting

- Sponsored apprenticeships or internships are another way to get training, so include those keywords when searching for job posts online

- Fabricators can also learn their skills via specialized programs like those from The Fab School. Check out related course offerings from Coursera, too!

- Optional certification programs can demonstrate Equipment Fabricators' commitment to quality, such as:

- Equipment Fabricators don’t need to attend a four-year university. But a certificate or associate’s at a technical school or community college will come in handy

- 수업료, 할인 및 지역 장학금 기회 비용을 고려하십시오 (연방 지원 이외에)

- Think about your schedule and flexibility when deciding whether to enroll in an on-campus, online, or hybrid program. Many relevant courses will need to be done in person to get hands-on experience

- 졸업생에 대한 프로그램 취업 통계 검토하기

- Sign up for plenty of math, physics, computer science, materials science, and shop classes in high school

- 자율 학습을 통해 기계 도면 및 청사진 읽기에 대한 학습을 고려해 보세요.

- Coursera, Udemy 또는 기타 사이트에서 온라인 임시 수업을 수강하세요.

- Enroll in a community college or vocational/technical school program to learn fabrication methods, welding, CAD/CAM, CNC machining, etc.

- Knock out a certification program such as AISC’s Certified Fabricator or AWS Certified Welder

- 근력과 체력을 키울 수 있는 피트니스 프로그램에 참여하세요.

- Get some real-world job experience via part-time jobs or internships related to fabrication or shop work

- Request to do an informational interview with a working Equipment Fabricator to learn about their jobs

- 향후 작업 참조 역할을 할 수 있는 연락처 추적

- Study books, articles, and video tutorials related to traditional and modern fabrication processes, tools, and equipment

- 온라인 포럼에 참여하여 질문하고 노련한 전문가로부터 배우십시오.

- 전문 조직과 협력하여 배우고, 공유하고, 친구를 사귀고, 네트워크를 성장시키십시오(리소스 > 웹사이트 목록 참조).

- 이력서 작성을 일찍 시작하십시오. 진행하면서 계속 추가하여 아무것도 놓치지 않도록하십시오.

- 인디드닷컴, 링크드인, 글래스도어, 몬스터, 커리어빌더, 심플리히어드, 집리크루터와 같은 채용 포털을 확인하세요.

- Look on Craigslist for job postings from smaller local companies

- Make a list of local equipment manufacturing companies and visit their websites’ career pages frequently

- Advertise your services online, such as on LinkedIn or via a website

- Seek out apprenticeships or internships sponsored by employers, unions, or trade associations

- Ask a working Equipment Fabricator for job-seeking tips

- Visit your school’s career center for assistance finding job fairs, writing a resume, and connecting with recruiters

- 동급생들과 연락을 유지하고 네트워크를 활용해 취업 정보를 얻으세요. 대부분의 일자리는 여전히 개인적인 인맥을 통해 찾습니다.

- 교수자, 이전 상사 및/또는 동료에게 개인 추천을 해줄 의향이 있는지 물어봅니다. 사전 허가 없이 그들의 개인 연락처 정보를 제공하지 마세요.

- Check out some Equipment Fabricator-related resume examples and sample interview questions

- Practice doing mock interviews and learn how to dress appropriately for interviews

Master your current job but let your supervisor know you’re interested in career progression. Express your willingness to complete additional training

- Study equipment and software operation manuals and become proficient with the tools you use

- Collaborate well with others and communicate clearly and honestly about the details of a project you’re assigned. If there is a challenge, explain it and try to offer solutions

- Ensure projects are kept on schedule and on-budget

- Keep track of fabrication, welding, and machining trends and advancements

- Consider specializing and getting advanced certifications in a challenging area, such as gas tungsten arc or laser hybrid welding

- 소규모 조직에서 근무하는 경우, 더 많은 급여를 받거나 더 높은 경력 목표를 달성하기 위해 더 크거나 다른 유형의 조직에 입사 지원해야 할 수도 있습니다.

- 고급 타사 인증을 완료하는 것도 도움이 될 수 있습니다. 옵션은 다음과 같습니다:

- AISC’s Certified Fabricator

- AWS Certified Welder

- Certified Composite Technician

- Certified Robotic Arc Welding

- National Institute for Metalworking Skills certifications

- NCCER’s Certified Metal Fabricator

- SME’s Certified Manufacturing Technologist

- A bachelor’s in mechanical engineering or a related field can open up additional career opportunities and provides a deeper understanding of engineering principles, materials science, and design concepts

웹사이트

- American Composites Manufacturers Association

- American Foundry Society

- 철강 건설의 미국 연구소

- American Machine Tool Distributors’ Association

- 미국 기계학회

- 미국 용접 학회

- Fabricators & Manufacturers Association, International

- 증권 시세 표시기

- International Association of Sheet Metal, Air, Rail, and Transportation Workers (SMART)

- National Center for Construction Education and Research (NCCER)

- 국립 금속 가공 기술 연구소

- 전국 툴링 및 가공 협회

- 정밀 가공 제품 협회

- Society of Manufacturing Engineers (SME)

책

- Composite Material Fabrication Handbook #1, by John Wanberg

- Learn to Weld: Beginning MIG Welding and Metal Fabrication Basics, by Stephen Christena

- Sheet Metal Workers Pocket Manual, by Fred Schumacher and Calude Zinngrabe

- Welding for Beginners: The Secrets To Welding, Cutting, and Shaping Metal Like a True Professional, by Cosmo Castro

Equipment Fabricator can be a very rewarding career choice! It’s filled with opportunities to do creative work with your hands, making custom pieces of equipment to help employers or clients overcome challenges and reach their objectives. But if this doesn’t sound quite right for you, here are some related occupations to consider:

- Aircraft Structure, Surfaces, Rigging, and Systems Assembler

- 보일러 메이커

- Coil Winder, Taper, and Finisher

- Electrical and Electronic Equipment Assembler

- Electromechanical Equipment Assembler

- Engine and Other Machine Assembler

- Fiberglass Laminator

- 산업 기계 정비사

- 철공 노동자

- Machinery Maintenance Worker

- Metal and Plastic Machine Worker

- 밀러라이트

- 판금 작업자

- 구조용 금속 제작자 및 피팅

- Timing Device Assembler

- 용접공

뉴스 피드

주요 채용 정보

온라인 과정 및 도구